BMC conical filters for direct air intake can be installed on most types of engine by removing the original airbox. BMC direct induction conical filters are manufactured using a characteristic red rubber that allows the connection of the intake to be particularly resistant to both engine stress and heat without suffering from deformations caused by the high temperature. The special filtration mesh allows the production of filters with a power up to 700 HP without presenting problems of filter deformation.

BMC conical filters are available in two versions:

SA (Single Air) with simple lateral air flow - available in carbon top, metal top and plastic top versions;

TW (Twin Air) with central and lateral air flow - available in metal top and plastic top versions.

The panel / cylindrical air filter is commonly referred to as "replacement air filter". It is installed in the vehicle's original airbox to replace the OEM air filter. It is made of highly performing materials that allow an increased air flow combined with a more efficient filtration, guaranteeing containment of all impurities from as small as 7 microns (compared to OEM's 10 microns).

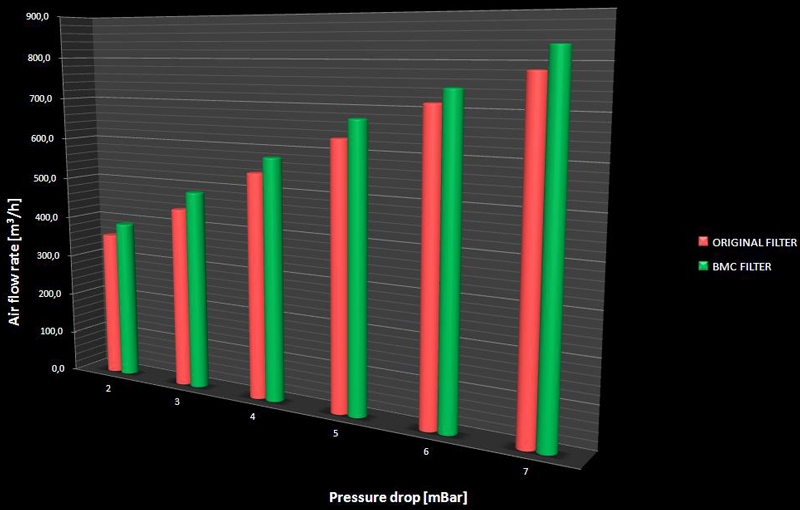

- Air flow chart for a sample BMC air filter against an OEM paper filter

- Temperature 25C? - Humidity 25% - Pressure 1020mbar

- Test ran with oem airbox, and the related air flow constrictions.

- This chart has a pure illustrative purpose and does not refer to the present filter.

BMC filters are made of a multi-layered cotton gauze soaked with low viscosity oil covered with an epoxy coated alloy mesh to ensure protection from petrol fumes and oxidization due to air humidity. All BMC air filters are pre-oiled, and they can be washed and regenerated by using the appropriate BMC regeneration kit.